- Home

- /

- News

- /

- Industry News

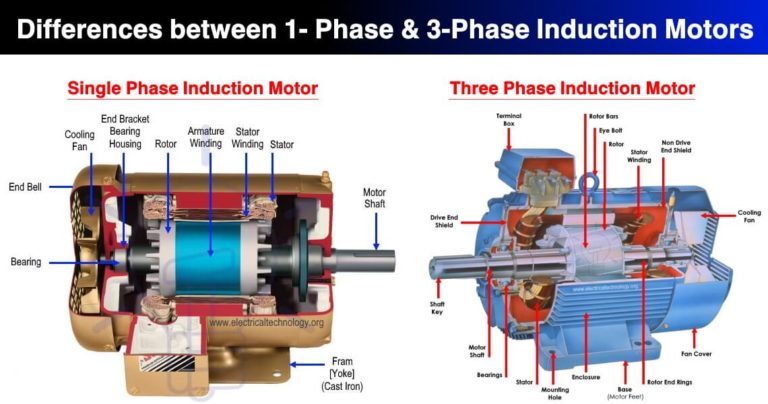

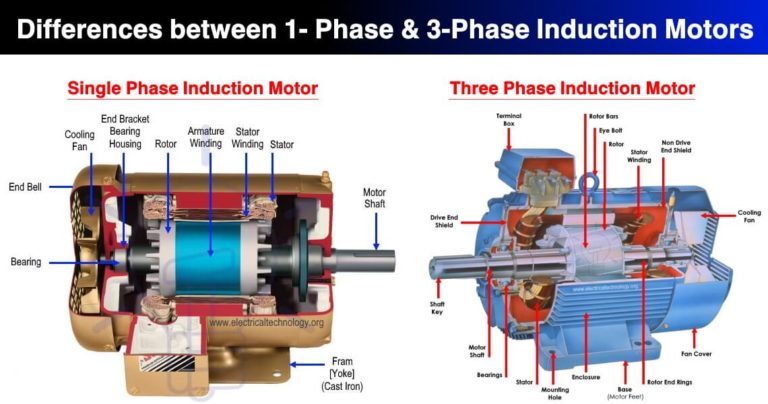

Difference Between Single Phase & Three Phase Induction Motor

The Induction motor is a type of AC motor that works on the principle of electromagnetic induction between the stator and rotor. The stator is the stationary part of the motor and the rotor is the rotary part.

The Induction motor is also known as asynchronous motor because its rotor rotates at a speed less than the theoretical synchronous speed of the motor. Induction motors can be designed to operate either on single phase or three phase power supply (refer to articles “differences between single phase and three phase power supply” for further information). The rotor of induction motor rotates due to the rotational magnetic field RMF generated by the stator windings surrounding it. The single phase supply can’t generate RMF because the windings carry the same current that various at the same time.

Therefore, it requires extra starting mechanism. While three phase supply can easily generate RMF because the windings carry 3 same frequency current having phase difference that generates a smooth RMF. So we can say that the major difference is that single phase induction motors are not self-starting while the three phase induction motor are self-start. You may know more about the basic information about AC and DC Current and Voltage in the previous post.

Single Phase Induction Motor

Single phase induction motor is a type of asynchronous AC motor that runs on single phase power supply. It is low power motor usually used in home and offices where single phase power is supplied from the utility poles. They are not self-starting motor which is why it needs a starting mechanism such as a capacitor starting technique. Since single phase AC can’t generate RMF, it utilizes a capacitor to generate a 90° phase shift in the auxiliary winding to generate RMF.

Such motor is called capacitor starting induction. Few other types of motor based on their starting mechanism are split phase induction motor, capacitor start capacitor run induction motor, shaded pole induction motor etc. The RMF generated by single phase is not very smooth because it is generated using a capacitor using auxiliary winding at 90°. The motor is subjected to vibrations and generates noise during its operation. It also wears out its lifespan.

The single phase supply is less reliable and more expensive than a three phase supply. Its power supply is affected by a fault in the line. The copper loss is greater for the same rated current since the current flows through only one winding. This is why their efficiency is lower than three phase motors. It also ends up increasing the size of the motor to tolerate the high current in the windings. It is relatively larger in size than three phase motor having same power ratings.

Since the single phase AC supply is easily available in houses and offices and the mechanical load required to drive is very small, the single phase induction motor is a better choice. It requires two conductors instead or 3 or 4 conductors which reduces the cable cost. Therefore, the single phase motors are economical for driving small loads. The design and construction is very simple, it use only two windings i.e. main winding and auxiliary winding.

Three Phase Induction Motor

Three phase induction motor is a type of AC asynchronous motor that runs on three phase power supply. it can either run in star configuration or delta configuration depending on the requirement. It is a heavy power rated motors only used in industries. It can easily generate RMF in the stator windings, thanks to the three alternating currents flowing in the windings that are 120° apart. It allows a smoothly rotating magnetic field far better the capacitor start single phase motor.

The RMF generated by three phase is very smooth which allows very smooth operation of the motor without any vibration and noises. Three phase supply is very reliable and very economical as compared to single phase. The power supply is not affected by a fault in one line. The stators windings share the current to reduce the cupper losses in the more. Thus they are more efficient.

These motors are usually used for driving very heavy mechanical loads in industries since they offer best efficiency and performance at higher power ratings. The motor losses are far more less than using a single phase motor having same ratings. Thus it ends up being cheaper than single phase motor. The design construction is relatively complex and causes to increases the manufacturing cost of the motor. it is why they are relatively quite expensive.

Therefore, it requires extra starting mechanism. While three phase supply can easily generate RMF because the windings carry 3 same frequency current having phase difference that generates a smooth RMF. So we can say that the major difference is that single phase induction motors are not self-starting while the three phase induction motor are self-start. You may know more about the basic information about AC and DC Current and Voltage in the previous post.

Single Phase Induction Motor

Single phase induction motor is a type of asynchronous AC motor that runs on single phase power supply. It is low power motor usually used in home and offices where single phase power is supplied from the utility poles. They are not self-starting motor which is why it needs a starting mechanism such as a capacitor starting technique. Since single phase AC can’t generate RMF, it utilizes a capacitor to generate a 90° phase shift in the auxiliary winding to generate RMF.

Such motor is called capacitor starting induction. Few other types of motor based on their starting mechanism are split phase induction motor, capacitor start capacitor run induction motor, shaded pole induction motor etc. The RMF generated by single phase is not very smooth because it is generated using a capacitor using auxiliary winding at 90°. The motor is subjected to vibrations and generates noise during its operation. It also wears out its lifespan.

The single phase supply is less reliable and more expensive than a three phase supply. Its power supply is affected by a fault in the line. The copper loss is greater for the same rated current since the current flows through only one winding. This is why their efficiency is lower than three phase motors. It also ends up increasing the size of the motor to tolerate the high current in the windings. It is relatively larger in size than three phase motor having same power ratings.

Since the single phase AC supply is easily available in houses and offices and the mechanical load required to drive is very small, the single phase induction motor is a better choice. It requires two conductors instead or 3 or 4 conductors which reduces the cable cost. Therefore, the single phase motors are economical for driving small loads. The design and construction is very simple, it use only two windings i.e. main winding and auxiliary winding.

Three Phase Induction Motor

Three phase induction motor is a type of AC asynchronous motor that runs on three phase power supply. it can either run in star configuration or delta configuration depending on the requirement. It is a heavy power rated motors only used in industries. It can easily generate RMF in the stator windings, thanks to the three alternating currents flowing in the windings that are 120° apart. It allows a smoothly rotating magnetic field far better the capacitor start single phase motor.

The RMF generated by three phase is very smooth which allows very smooth operation of the motor without any vibration and noises. Three phase supply is very reliable and very economical as compared to single phase. The power supply is not affected by a fault in one line. The stators windings share the current to reduce the cupper losses in the more. Thus they are more efficient.

These motors are usually used for driving very heavy mechanical loads in industries since they offer best efficiency and performance at higher power ratings. The motor losses are far more less than using a single phase motor having same ratings. Thus it ends up being cheaper than single phase motor. The design construction is relatively complex and causes to increases the manufacturing cost of the motor. it is why they are relatively quite expensive.

Key: Vertical 3 Phase ac induction motors, electric motor, Vertical Inverter Duty motor, DC Brake motor Oil Pressure Motor, helical gear motor, AC mini Induction DC gear motor, Gear reducer motor series, NMRV NRV worm reducer series, Worm reducer series, Horizontal Inverter duty, worm gear series, ac motor, vertical gearmotor, helical horizontal gearmotor, gear reduce motor, bevel gearmotor, cyclo gear motor, NMRV gear motor, worm reducer

Newer articles

- What are common gearmotor types and variations? (17/10/2020)

- Everything to Know About Worm Gears and the Benefits of Collaborating With A Manufacturer (19/10/2020)

- What Are Gear Motors? (22/10/2020)

- Gearboxes and Geared motors (20/10/2020)

- What You Need to Know About Gearbox Service Factor (16/10/2020)

- When Should I Change the Oil in My Reducer? (15/10/2020)

- Single Phase Induction Motor and Its Working (12/10/2020)

- Gearbox Service Factor: What Is It & Why Is It Important? (13/10/2020)

- Gearbox Noise & Vibration: Shaft Mount Reducer Solutions (14/10/2020)

- Single-Phase Motor - Types, Uses, Advantages and Disadvantages (09/10/2020)

Older articles

- Single phase Induction Motors (08/10/2020)

- Helical bevel gear reducer (07/10/2020)

- What is inrush current in an AC motor and why does it matter? (06/10/2020)

- How do shear pin torque limiters work and when are they used? (04/10/2020)

- What is direct torque control (DTC) for AC induction motors? (03/10/2020)

- What function do thermistors and KTY sensors serve in motors and gearmotors? (02/10/2020)

- What is the Machinery Directive and how does it relate to motion system safety? (30/09/2020)

- Geared Motor Types and Their Importance (30/09/2020)

- What is the structure of a gear motor? (29/09/2020)

- Difference between drum motors and gear motors for food conveying (29/09/2020)

Join